MIL-PRF-16552F

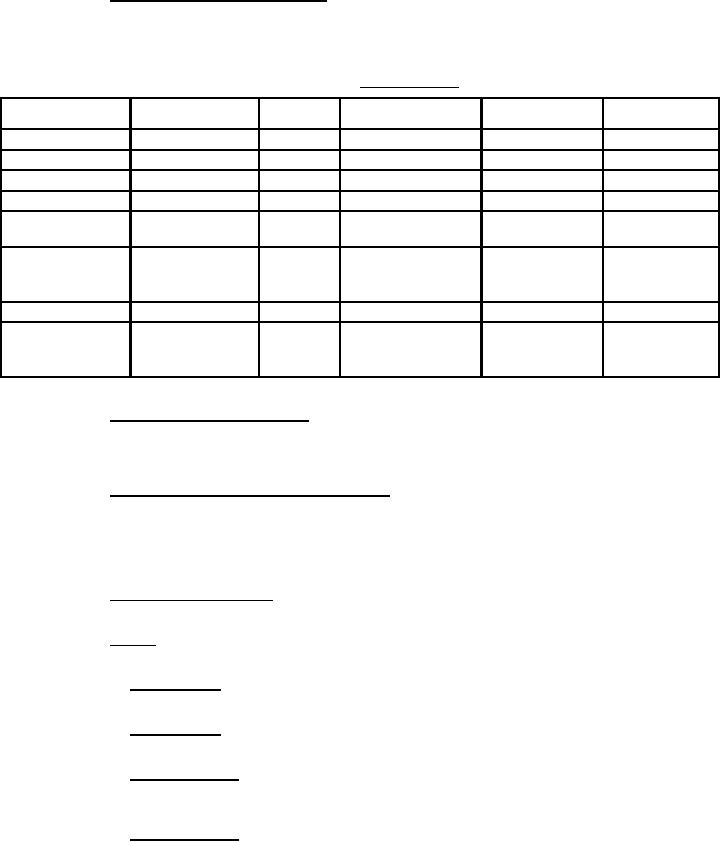

4.2 First article inspection. First article inspection shall consist

of the examination of 4.6 and tests specified in Table II. The tests

specified shall be performed on each size filter.

TABLE

II.

Test Agenda.

Verifi-

Tests

Requirements

cation

First Article

Conformance

Periodic

Resistance

3.12.1

4.6.1

All

All

All

Arrestance

3.12.1

4.6.2

All

-----

-----

Dust Loading

3.12

4.6.3

All

-----

All

Cleanability

3.13

4.6.4

All

-----

-----

Shock Corner

3.10

4.6.5

All

-----

-----

Drop Test

Composite

3.2.1

4.6.6

First

-----

First

Material

Production

Production

Unit

Unit

Permeability

3.2.4

4.6.7

All

-----

-----

Strength

3.8.b

0

First

-----

-----

Production

Unit

4.3 Conformance inspection. Conformance inspection shall consist of

the tests as specified in Table II. The tests specified shall be performed on

each size filter. Any unit which fails to meet any specified requirements

shall be rejected.

4.4 Periodic conformance inspection. Periodic

tests are required to

ensure continuing satisfactory operation of identical

units. The tests are

required under any contract or purchase order for air

filters of existing

design when the invitation to bid is dated 4 years or

more subsequent to the

date of the last previous test of an identical unit.

Periodic tests shall

consist of the tests specified in Table II.

4.5 Composite material. Filters constructed of composite material

shall meet the material requirements of 4.6.6.

4.6

Tests.

Tests shall be conducted in accordance with 4.6.1 through

4.6.7.

4.6.1

Resistance. Resistance shall be determined in accordance with

ASHRAE 52.1-1992, resistance versus air flow measurements.

4.6.2

Arrestance. Arrestance shall be tested in accordance with

ASHRAE 52.1-1992, determination of synthetic dust weight arrestance.

4.6.3

Dust loading. Dust loading effects shall be tested in

accordance with the requirements for disposable and non-renewable filters of

ASHRAE 52.1-1992.

4.6.4

Cleanability. Cleanability shall be determined after the filter

is loaded with dust in accordance with 4.6.3. Cleaning shall be by means of a

2

stream of hot water at a pressure of 60 to 80 pounds per square inch (lb/in ).

If cleaning by this means reduces the resistance to air flow to within 0.01

inch water gauge of its initial value, with the filter unoiled both before and

after the test, the specimen shall be considered acceptable in regard to

cleanability.

6

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business