MIL-PRF-16552F

d. Be compatible for constant contact with food grade lubricating oil,

United States Department of Agriculture rating USDA H1.

3.10 Corner shock resistance.

Filter frames shall withstand shock or

impact to the corners.

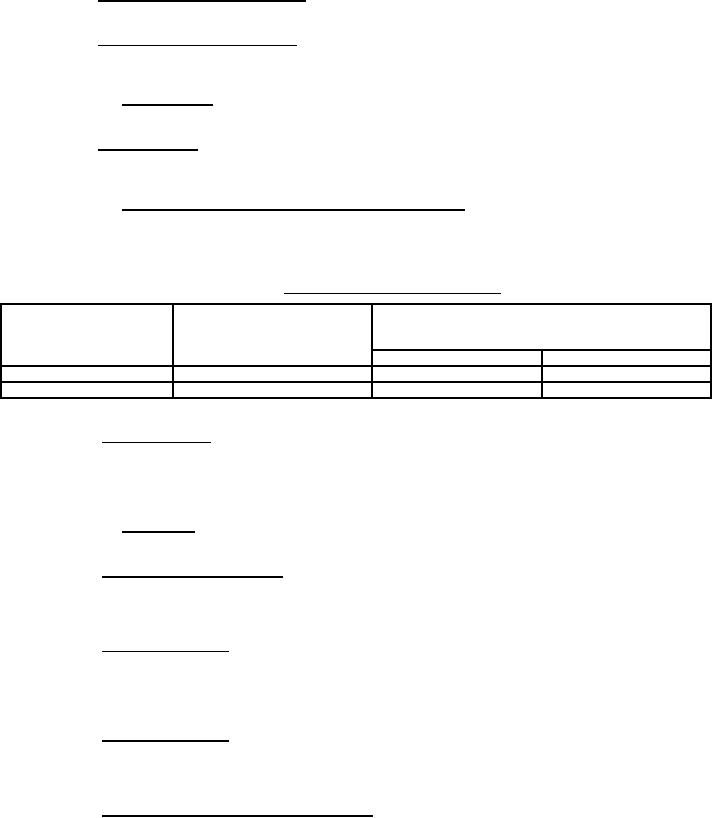

3.11 Interface requirements. To permit removability and

interchangeability, sizes of air filters shall be limited to those shown on

Figure 1.

3.11.1 Tolerances.

Tolerances of the air filters shall be as shown on

Figure 1.

3.12 Performance. The air filter, when tested at face velocities of 500

and 625 feet per minute, shall have initial efficiencies and a dust load

capacity of at least 2.65 ounces per square foot of face area when loaded.

3.12.1 Pressure loss (resistance to air flow). At the specified face

velocities, the initial resistance and the resistance when loaded with at

least 2.65 ounces of test dust per square foot shall not exceed those shown in

Table I.

TABLE I.

Performance Requirements.

Pressure loss

Face Velocity

Average synthetic

(feet per minute)

dust weight

inches water gauge

arrestance

(per cent)

Initial

Loaded

500

65

0.15

0.65

625

70

0.25

0.95

3.13 Cleanability. The air filter shall be capable of being cleaned

using hot water at a temperature of 190 degrees Fahrenheit and detergent. The

resistance of the filter shall be increased by not more than 0.01-inch water-

gauge from the initial air-flow resistance after having been loaded with dirt

and cleaned.

3.13.1 Drainage. Provide means on all sides of the filter frame to

ensure complete drainage after cleaning.

3.14 Filter media support. The media shall be attached to the frame in

a way that prevents splitting, dislodging, slumping or separation from the

frame under maximum air velocity and filter resistance conditions. The filter

media shall be protected on both faces by suitable guards.

3.15 Filter removal. An integral means for removal of a filter from a

filter housing shall be provided on two adjacent sides of the filter. This

provision shall not interfere with sliding the filter into a filter housing,

shall be self-storing, and shall not project beyond the outer faces of the

frame.

3.16 Operating life.

The filters shall have an operating life of 100

wash and dry cycles.

4. VERIFICATION

4.1 Classifications of inspections.

The inspections specified herein

are classified as follows:

a. First article inspection (see 4.2)

b. Conformance inspection (see 4.3)

c. Periodic conformance inspection (see 4.4)

5

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business