MIL-PRF-2939G

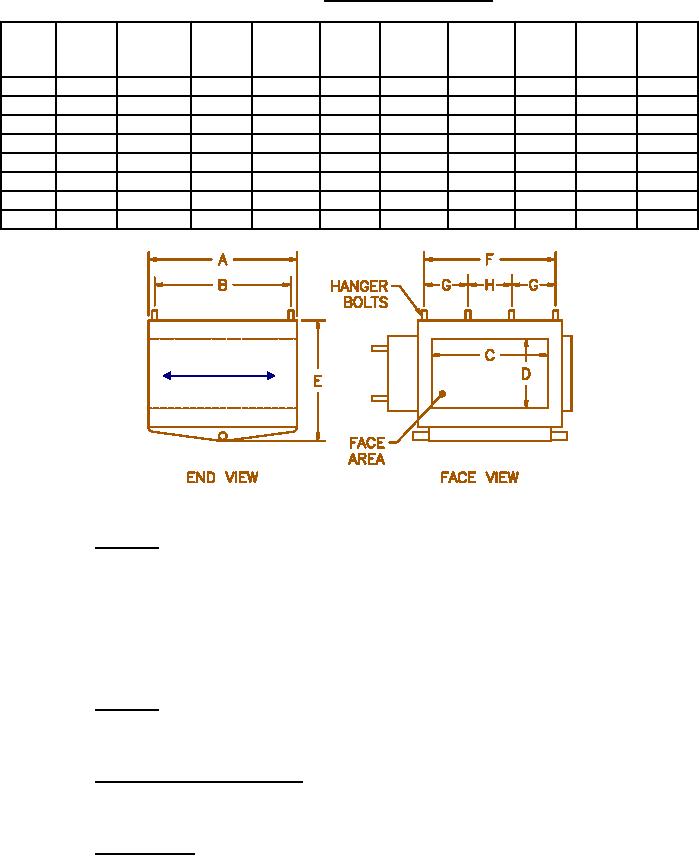

TABLE III.

Physical Dimensions.

Size

Face

Dry Wt

A

B

C

D

E

F

G

H

Area

Max

sq ft

Lbs.

In.

In.

In.

In.

In.

In.

In.

In.

61

.57

106

15

13.75

11.75

7.0

12.12

13.25

x

x

62

.90

118

15

13.75

14.00

9.25

14.38

15.50

x

x

63

1.35

169

15

13.75

21.00

9.25

14.38

22.50

x

x

64

2.00

212

15

13.75

25.00

11.5

16.62

26.50

x

x

65

3.00

280

15

13.75

31.5

13.75

18.88

33.0

16.5

x

66

5.00

404

15

13.75

39.5

18.25

23.38

41.0

13.68

13.62

67

7.50

766

17.63

16.

39.5

28.44

34.25

41.12

13.75

13.62

68

10.0

830

17.63

16.

39.5

37.44

43.25

41.12

13.75

13.62

AIR

FLOW

Class 1 Cooling Coil Interface Dimensions

3.13.10

Headers. The cooling coils shall have a supply header and a return

header. The headers shall be enclosed within the coil end cover but not in the

air stream. The headers shall be secure to the coil end cover to relieve the

header joints from stresses due to external pipe whip. The supply and return

connections to the chilled water system shall be union connections or other

connections meeting the flexibility and strength requirements of union type

connections. Connections shall be rated for a service pressure of 300 pounds

per square inch.

3.13.11

Hangers. Hangers shall have a tensile strength of a least 85,000

pounds per square inch and a yield strength of at least 35,000 pounds per

square inch.

3.13.12

Cooling element support. Intermediate supports shall be provided for

the cooling elements as necessary to prevent piping from sagging, and to

satisfy vibration and shock requirements.

3.13.13

Coil baffle. Baffles or other means shall be built into the cooling

coil to prevent condensate draining to the coil bottom from being blown into

connecting ductwork.

13

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business