MIL-DTL-22576A

3.4.2 Perforations. The bellmouth and bottom plate of each terminal shall be perforated with 0.068-inch

diameter holes on ¼-inch centers. The total opening of the holes shall be approximately 6.5 percent of area of the

sheet.

3.4.3 Burrs and irregularities. The edges of vanes, rings, collars, and other parts shall be free of burrs, tears, or

irregularities, which will tend to increase noise or turbulence in the air stream. In spinning or forming the bellmouth

and bottom plate some distortion of the holes in the perforated sheets is unavoidable.

3.4.4 Tears. There shall be no tears or split material between holes.

3.4.5 Cleaning. All brazed and welded joints shall be cleaned of flux and residue.

3.5 Label plates. Each terminal shall carry an identifying label. The label information may be pressed into the

throat piece, or a plate or a permanent corrosion-resistant label secured with adhesive may be attached to the throat

piece. The following information shall be shown by the label:

a.

Circular diffusing terminal

b.

Size

c.

Stock number

d.

Contract number or order number

e.

Manufacturer's name and Commercial and Government Entity (CAGE) code

3.6 Drawings. Drawings shall be as specified (see 6.2).

3.7 Shock. Unless otherwise specified (see 6.2), the terminal shall pass the high-impact shock tests specified in

MIL-S-901 for Grade A, Class I equipment.

4. VERIFICATION

4.1 Classification of inspections. The inspection requirements specified herein are classified as follows:

a.

First article inspection (see 4.2).

b.

Conformance inspection (see 4.3).

4.2 First article inspection. First article inspection shall be performed on each size when a first article sample is

required (see 3.1). This inspection shall include the examination of 4.4 and the tests of 4.5 (see table I).

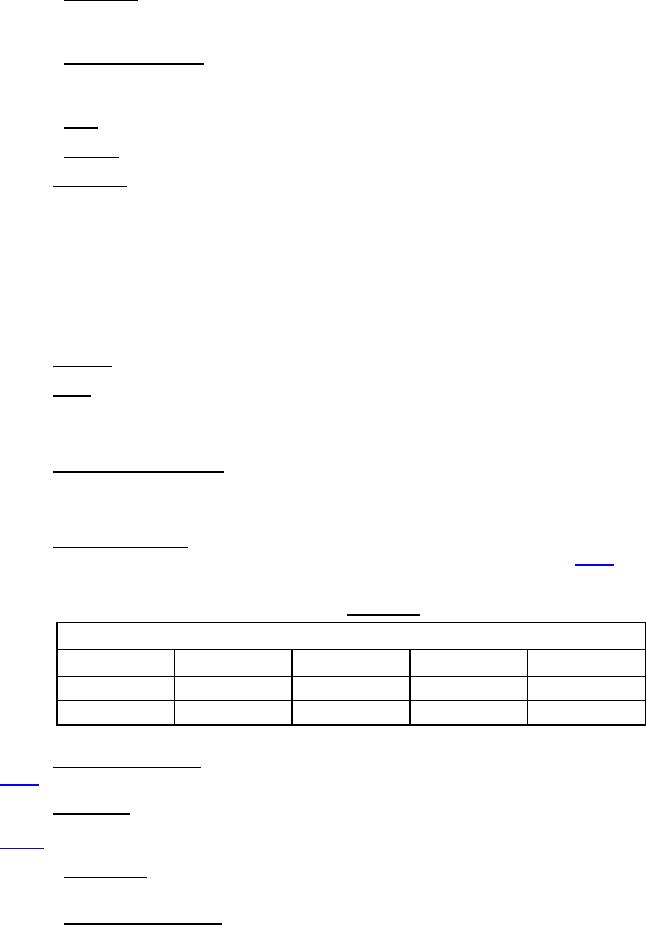

TABLE I. Test agenda.

Applicability of test to circular diffusing terminal

Tests

Requirement

Test

First article

Conformance

Shock

All

Shake

All

All

4.3 Conformance inspection. Conformance inspection shall include the examination of 4.4 and the tests of

table I.

4.4 Examination. Each of the sample diffusing terminals selected in accordance with 4.4.1 and 4.4.2 shall be

examined and measured to verify compliance with this specification. Examination shall be conducted as specified in

table II. Any diffusing terminal in the sample containing one or more defects shall be rejected.

4.4.1 Inspection lot. All diffusing terminals of the same size offered for delivery at one time shall be

considered a lot for purposes of sampling and inspection.

4.4.2 Sampling for examination. Sample diffusing terminals shall be selected at random from each lot in

accordance with ANSI/ASQ Z1.4 at Inspection Level II for the examination specified in 4.4.

3

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business